- Clean Room

- HVAC System

- Water for Pharmaceutical Use

- Sanitary Distribution Piping

- Solution Formulation System

- CIP/SIP System

- Control System

- Tablet Production

- Capsule Production

- Powder Vial Production

- Liquid Vial Production

- Oral Liquid Production

- Eye Drop Production

- IV Solution Production

- Cream/Ointment Production

- Soft Gelatin Production

- Pilot Production

- Ampoule Production

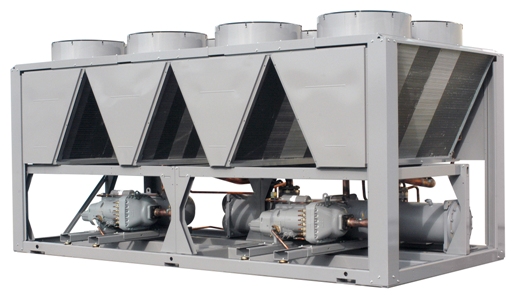

30XA262G-1502G "Aquaforce" Air Cooled Screw Chiller

The Aquaforce liquid chillers are the premium solution for industrial and commercial applications where installers, consultants and building owners require optimal performances and maximum quality

Benefits:

Extremely high full load and part load energy efficiency leads to extremely low operation cost.

Low operating sound with no intrusive low-frequency noise, creates a better working/living environment.

Environment sound refrigerant HFC-134a of zero ozone depletion potential.

Easy and fast installation to reduce on-site installation time.

Exceptional endurance tests ensure superior reliability to minimize chiller down-time.

Features

Economical operation

Extremely high full load and part load energy efficiency:

- New twin-rotor screw compressor equipped with a high efficiency motor and a variable capacity valve that permits exact matching of the cooling capacity to the load.

- Flooded multi-pipe evaporator to increase the heat exchange efficiency, configured with aluminium cladding (standard) to improve thermal insulation and prevent energy loss.

- Electronic expansion device allows operation at a lower condensing pressure and improved utilization of the evaporator heat exchange surface (superheat control).

- Economizer system with electronic expansion device to achieve enhanced cooling capacity and efficiency.

- Average COP of 3.2 at nominal conditions and average integrated part load value (IPLV) of 4.4.

Quiet operation

■ Compressors

- Discharge dampers integrated in the oil separator (Carrier patent).

- Silencer on the evaporator return line.

- Acoustic compressor and oil separator enclosure (option) reduce the radiated noise.

■ Condenser section

- Condenser coils in V-shape with an open angle, allows quieter air flow across the coil.

- Low-noise Flying Bird fans (Carrier patent) enjoy quieter operation and never generate intrusive low frequency noise.

- Rigid fan mounting preventing start-up noise (Carrier patent).

Environmental sound

■ HFC-134a refrigerant

- Refrigerant of the HFC group with zero ozone depletion potential.

■ Leak-tight refrigerant circuit

- Reduction of leaks as no capillary tubes and flare connections are used.

- Verification of pressure transducers and temperature sensors without transferring refrigerant charge.

Easy and fast installation

■ Integrated hydronic module (option)

- Single or dual pump (as required) with operating time balancing and automatic changeover to the back-up pump if a fault develops

- Water filter protecting the water pump against circulating debris

- High-capacity membrane expansion tank ensures pressurization of the water circuit

- Thermal insulation and aluminum protection

- Pressure gauge to check filter pollution and measure the system water flow rate

- Water flow control valve

■ Simplified electrical connections

- Main disconnect switch with high trip capacity

- Transformer to supply the integrated control circuit (400/24V)

■ Fast commissioning

- Systematic factory operation test before shipment

- Quick-test function for step-by-step verification of the instruments, expansion devices, fans and compressors

Absolute reliability

■ Screw compressors

- Industrial-type screw compressors with oversized bearings and motor cooled by suction gas.

- All compressor components are easily accessible on site minimizing down-time.

- Electronic motor protection against overloads and power supply faults (loss of phase, phase reversal).

■ Evaporator

- Thermal insulation with aluminum cladding for perfect resistance against outside aggression(mechanical and UV protection).

■ Exceptional endurance tests

- Partnerships with specialized laboratories and use of limit simulation tools (finite element calculation) for the design of critical components.

- Transport simulation test in the laboratory on a vibrating table. The test is based on a military standard and equivalent to 4000 km by truck.

- Salt mist corrosion resistance test in the laboratory for increased corrosion resistance.

|

Model: |

30XA262G-1502G |

|

Cooling Capacity: |

254 - 1551(kW) |

|

Refrigerant: |

HFC-134a |

|

Model |

Cooling Capacity |

|

30XA |

kW |

|

262G |

254 |

|

282G |

284 |

|

342G |

333 |

|

442G |

446 |

|

482G |

500 |

|

602G |

632 |

|

702G |

687 |

|

852G |

851 |

|

1002G |

1008 |

|

1202G |

1272 |

|

1352G |

1480 |

|

1502G |

1551 |

Key Words:

Pharmaceutical Machinery, Pharmaceutical Engineering, Pharmaceutical Equipment,

Packaging Machinery, GMP Machinery, Pharmaceutical Industry, Pharmaceutical Technology

cGMP Service, cGMP Solutions, cGMP Validation